60245 IEC 57 YZW Neoprene Rubber Cord

Flexible cable with neoprene or synthetic elastomer sheath, rated 300/500V and 60°C. Features stranded bare/tinned copper conductors (Class 5), oil-resistant insulation, and robust protection against abrasion, moisture, and weather. Complies with IEC 60245 standards. Ideal for industrial machinery, portable tools, outdoor equipment, and harsh environments. RoHS-compliant, ensuring eco-friendly performance. Combines durability, flexibility, and resistance to chemicals for reliable power transmission in dynamic applications.

-

60245 IEC 57 YZW

-

Zhongxin

-

85444221

| Availability: | |

|---|---|

| Quantity: | |

Product Overview

The 60245 IEC 57 (YZW) Cord is a high-performance neoprene rubber sheathed cable engineered for reliable power transmission in challenging environments. This flexible synthetic elastomer cable features stranded bare or tinned copper conductors, ensuring excellent flexibility and conductivity for dynamic applications. Compliant with international IEC 60245 standards and RoHS regulations, it combines durability and eco-friendliness, making it a top choice for industrial and outdoor use. Designed to withstand harsh conditions, the cable’s robust construction delivers consistent performance in settings where abrasion, moisture, and chemical exposure are common.

Product Advantage

Superior Environmental Resistance

The neoprene sheath provides exceptional protection against oil, moisture, UV radiation, and mechanical stress, ensuring long service life even in extreme outdoor or industrial environments. Its resistance to harsh chemicals further enhances reliability in dynamic applications.

Enhanced Flexibility & Durability

Stranded Class 5 copper conductors enable excellent bending tolerance, making the YZW rubber cord ideal for portable tools and moving machinery parts. The combination of IE4-grade insulation and SE4-grade sheath ensures robust protection without compromising flexibility.

Global Compliance & Safety

Meeting IEC 60245-4, GB/T 5013.4, and JB/T8735.2 standards, the cable guarantees global safety compliance. RoHS-compliant materials eliminate hazardous substances, supporting eco-friendly operations and meeting international environmental requirements.

Technical Parameters

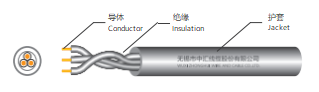

Core Construction

The cable features stranded bare or tinned copper conductors for optimal conductivity and corrosion resistance. Insulation is made of IE4-grade rubber that meets RoHS requirements, while the outer jacket uses SE4-grade neoprene or equivalent synthetic elastomer, ensuring robust protection and flexibility.

Operational Ratings & Standards

Rated for consistent performance at specified voltage and temperature levels, the 60245 IEC 57 cable adheres to strict international standards. It complies with multiple global certifications, ensuring compatibility with industrial systems worldwide and supporting safe power transmission in diverse settings.

Physical & Protective Features

The cable’s construction includes oil-resistant insulation and a weatherproof sheath, designed to withstand abrasion, moisture, and chemical exposure. Its lightweight design simplifies installation in confined spaces without sacrificing durability.

| Parameter | Details |

|---|---|

| Rating Temp | 60℃ |

| Rating Volt. | 300/500V |

| Reference Standard | GB/T 5013.4-2008/IEC 60245-4:2004/JB/T8735.2-2016 |

| Conductor | Stranded bare or tinned copper conductor |

| Insulation | IE4, PASS ROHS |

| Jacket | SE4, PASS ROHS |

| Application | Internal & exterior wiring for electronic appliances, power instruments, and auto equipments |

C×mm2 | Insulation | Jacket | Max Resistance (Ω/km, 20℃) | |||

Nom.Thick. (mm) | Nom.Dia. (mm) | Nom.Thick. (mm) | Nom.Dia. (mm) | |||

2× | 0.75 | 0.6 | 2.40 | 0.8 | 6.55 | 26 |

1.0 | 0.6 | 2.60 | 0.9 | 7.15 | 19.5 | |

1.5 | 0.8 | 3.30 | 1.0 | 8.75 | 13.3 | |

2.5 | 0.9 | 3.85 | 1.1 | 10.10 | 7.98 | |

4 | 1.0 | 4.65 | 1.2 | 12.00 | 4.95 | |

6 | 1.0 | 5.20 | 1.3 | 13.20 | 3.30 | |

3× | 0.75 | 0.6 | 2.40 | 0.9 | 7.15 | 26 |

1.0 | 0.6 | 2.60 | 0.9 | 7.55 | 19.5 | |

1.5 | 0.8 | 3.30 | 1.0 | 9.30 | 13.3 | |

2.5 | 0.9 | 3.85 | 1.1 | 10.80 | 7.98 | |

4 | 1.0 | 4.65 | 1.2 | 12.60 | 4.95 | |

6 | 1.0 | 5.20 | 1.3 | 14.10 | 3.30 | |

4× | 0.75 | 0.6 | 2.40 | 0.9 | 7.75 | 26 |

1.0 | 0.6 | 2.60 | 0.9 | 8.25 | 19.5 | |

1.5 | 0.8 | 3.30 | 1.1 | 10.35 | 13.3 | |

2.5 | 0.9 | 3.85 | 1.2 | 12.00 | 7.98 | |

4 | 1.0 | 4.65 | 1.3 | 14.10 | 4.95 | |

6 | 1.0 | 5.20 | 1.4 | 15.70 | 3.30 | |

C×mm2 | Insulation | Jacket | Max Resistance (Ω/km, 20℃) | |||

Nom.Thick. (mm) | Nom.Dia. (mm) | Nom.Thick. (mm) | Nom.Dia. (mm) | |||

5× | 0.75 | 0.6 | 2.40 | 1.0 | 8.60 | 26 |

1.0 | 0.6 | 2.60 | 1.0 | 9.20 | 19.5 | |

1.5 | 0.8 | 3.30 | 1.1 | 11.30 | 13.3 | |

2.5 | 0.9 | 3.85 | 1.3 | 13.20 | 7.98 | |

4 | 1.0 | 4.65 | 1.4 | 15.70 | 4.95 | |

6 | 1.0 | 5.20 | 1.6 | 17.60 | 3.30 | |

6× | 0.75 | 0.6 | 2.40 | 1.0 | 9.35 | 26 |

1.0 | 0.6 | 2.60 | 1.1 | 10.10 | 19.5 | |

1.5 | 0.8 | 3.30 | 1.2 | 12.50 | 13.3 | |

2.5 | 0.9 | 3.85 | 1.4 | 14.60 | 7.98 | |

4 | 1.0 | 4.65 | 1.5 | 17.25 | 4.95 | |

6 | 1.0 | 5.20 | 1.7 | 19.30 | 3.30 | |

3×1.5+1×1.0 | 0.8/0.6 | 3.30/2.60 | 1.1 | 9.90 | 13.3 | |

3×2.5+1×1.5 | 0.9/0.8 | 3.85/3.30 | 1.2 | 11.90 | 7.98 | |

3×4+1×2.5 | 1.0/0.9 | 4.65/3.85 | 1.3 | 14.00 | 4.95 | |

3×6+1×4 | 1.0/1.0 | 5.20/4.65 | 1.4 | 15.60 | 3.30 | |

Product Uses

Industrial Machinery Applications

Ideal for wiring industrial machinery, production lines, and heavy-duty equipment, the YZW elastomer cable delivers reliable power in high-stress manufacturing environments. Its flexibility supports continuous movement of machine components.

Portable Tools & Outdoor Equipment

Perfect for portable power tools, outdoor lighting systems, and construction equipment. The cable’s weatherproof and abrasion-resistant design ensures reliable performance in outdoor or temporary work sites.

Automotive & Electronic Appliances

Suitable for internal and external wiring of automotive equipment and electronic appliances. The cable’s oil and moisture resistance makes it a reliable choice for vehicle electrical systems and household devices exposed to harsh conditions.

FAQ

What makes the 60245 IEC 57 (YZW) Cord suitable for harsh environments?

The neoprene sheath and synthetic elastomer construction provide superior resistance to oil, moisture, UV, and mechanical stress, ensuring durability in extreme conditions.

Can the cable be used for portable tools?

Yes, its stranded copper conductors and flexible design make the YZW rubber cord perfect for portable tools that require frequent bending and movement.

Is the cable environmentally friendly?

Absolutely, both insulation and jacket are RoHS-compliant, free from hazardous substances like lead and mercury, supporting eco-friendly operations.

What standards does the cable comply with?

It meets IEC 60245-4, GB/T 5013.4, and JB/T8735.2 standards, ensuring global safety and performance compliance.